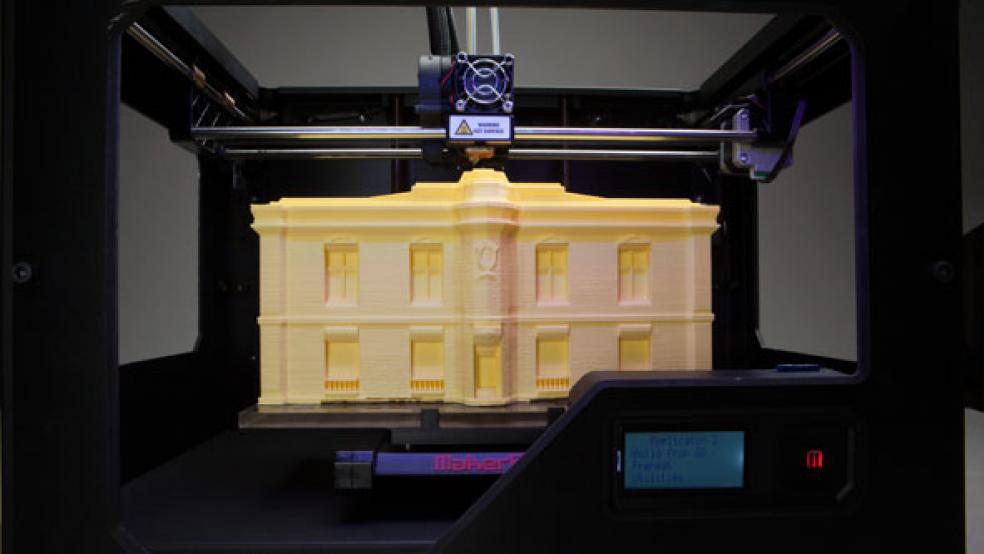

During his State of the Union address Tuesday night, President Obama shone a bright light on the 3D printing industry – also known as additive manufacturing – which is an advanced manufacturing and design process for making solid 3D objects from a digital file.

The burgeoning business includes just a handful of publicly traded companies right now, all of which are still small by market standards. 3D Systems Corporation (NYSE: DDD), based in Rock Hill, South Carolina, had revenue of $322 million in the 12 months through September 2012 and a market cap of $3.74 billion. Stratasys, Ltd. (NASDAQ: SSYS), based in Eden Prairie, Minnesota, had revenue of $188 million and a market value of $2.9 billion.

Another company in the sector, ExOne Co. (NASDAQ: XONE), went public just last week and is now valued at $358 million, while Proto Labs, Inc. (NYSE: PRLB) has a market cap of $1.28 billion.

RELATED: Can Obama Finally Fix American Manufacturing?

The stocks of these companies were racking up huge gains even before Obama called out the sector this week. 3D Systems has gained 224 percent over the last year – including a 4 percent pop on Wednesday – as investor enthusiasm for the technology has grown. “Though the technology has been around for more than two decades, investors’ optimism has improved dramatically,” wrote Jake Mann in Insider Monkey. A prime reason: the usability and affordability of the products. The price of 3D’s home printer, the Cube, for example, which turns ideas into physical objects, starts at $1,300.

Stratasys stock has done even better, rocketing 540 percent over the last year. ExOne shares surged 47 percent when they made their debut on the Nasdaq Stock Market last Thursday – the best of any IPO so far this year.

Three-dimensional printing technology cuts the time and cost involved in designing new products, since actual physical parts are created from digital input, in some cases using industrial-strength materials that range from metals to ceramics to glass. 3D Systems, which has been increasingly targeting the consumer market, is a member of the newly created National Additive Manufacturing Innovation Institute (NAMII) – based in Youngstown, Ohio, as the president highlighted. The company’s software is used to quickly design, communicate, prototype and produce functional parts and products, “empowering” customers to “create with confidence,” it says.

Comprised of members from industry, academia, government and workforce development resources “all collaborating with a singular, shared vision,” NAMII is a public-private partnership that promotes innovation and entrepreneurialism. Edward A. Morris, its director, said this week, “NAMII is trailblazing the way to transform the U.S. manufacturing industry once again into a dominant, global economic force.”

Current members of the public-private partnership include 3D Systems Corp., Northrop Grumman, Lockheed Martin Aeronautics, GE Global Research and Allegheny Technologies – as well as a number of universities, including Case Western Reserve, Lehigh, University of Texas at Austin, and Youngstown State University. The group’s goal is to transition 3D printing technology to the mainstream U.S. manufacturing sector.

Here’s what President Obama said about 3D printing in his State of the Union and why it matters:

“After shedding jobs for more than 10 years, our manufacturers have added about 500,000 jobs over the past three… There are things we can do, right now, to accelerate this trend. Last year, we created our first manufacturing innovation institute in Youngstown, Ohio. A once-shuttered warehouse is now a state-of-the art lab where new workers are mastering the 3D printing that has the potential to revolutionize the way we make almost everything. There’s no reason this can’t happen in other towns.”

The president also announced “the launch of three more of these manufacturing hubs, where businesses will partner with the Departments of Defense and Energy to turn regions left behind by globalization into global centers of high-tech jobs.”

But one thing the president didn’t mention is how individual tinkerers in this technology – the entrepreneurs of tomorrow, presumably – are already benefiting. Jonathan Shaw, a digital operations manager in northern New Jersey, owns a 3D printer as a hobby, he told The Fiscal Times, but says he can foresee the day when he “takes the plunge into mass-producing products or selling online.”

New materials “are already available to print with, as opposed to just polymer plastics,” says Shaw. “Soon, rather than waiting for a part to be in stock when your car breaks down, you can just print one. There are surgical uses and food-related uses. When my wife needed a ring holder for when she did dishes, I just ran downstairs and ‘printed’ one in under an hour. Is that life changing? No – but it could easily be applied as a new in-home business model.”

Shaw adds, “For small business, this can be a great way to prototype products and compete at a much higher level with minimal investment.”